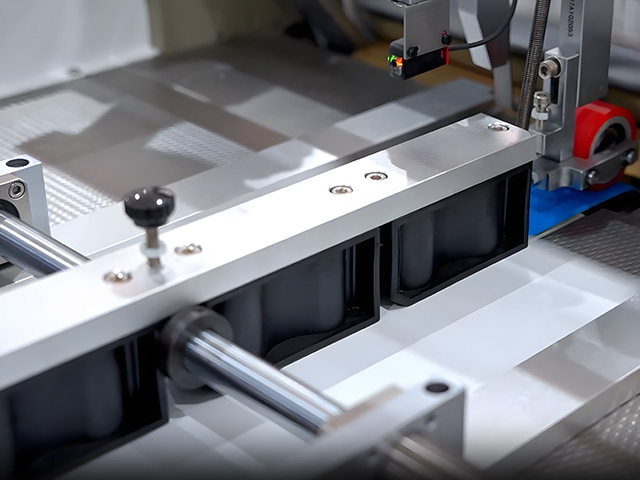

The Collapsible Box Production Line Solution is an integrated system designed to automate and streamline the manufacturing of collapsible boxes. These boxes are widely used in industries such as logistics, e-commerce, food, and retail due to their space-saving and reusable nature. The production line ensures high efficiency, precision, and consistency in box production, reducing labor costs and minimizing material waste.